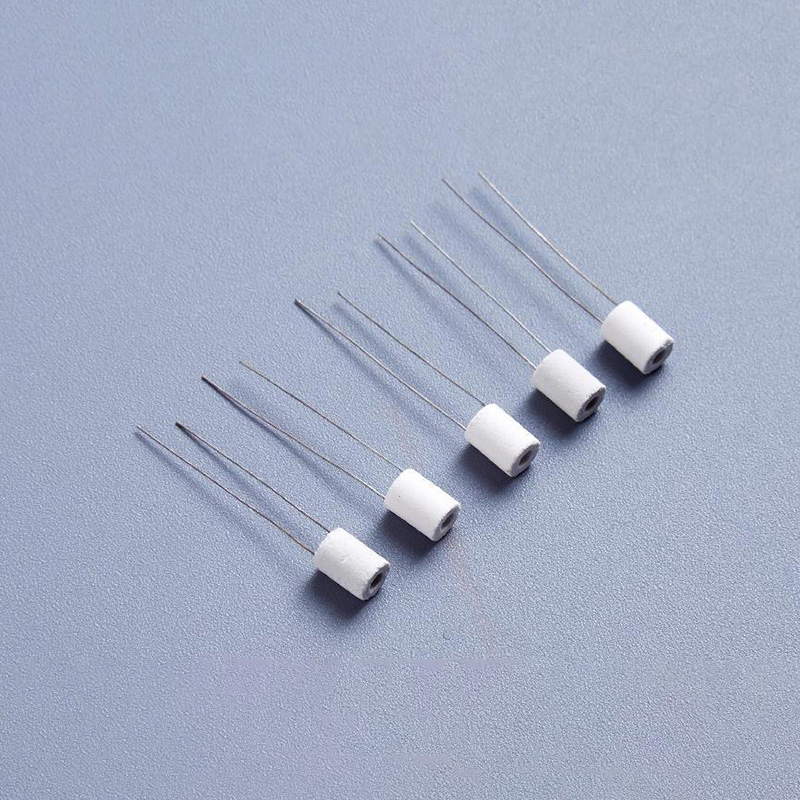

Tharollo ea vape ea ceramic ea coil

Silicore tekheniki ke sethala sa atomization se ipapisitseng le ho fumana tekano lipakeng tsa matla, mocheso le phallo.

Sefofane:

Tsela ea moea e ama ho tsoa ha oli, condensate, joalo-joalo Haeba tsela ea moea e sa boreleli, 'me mosi oa athomo o bokellana' me o lula tseleng ea moea, o tla kokobela; tselana ea moea ha e na sebopeho sa buffer ventilation. Ka tšebeliso ea e-liquid, moea o sebakeng sa polokelo ea oli oa eketseha, o etsa phapang ea khatello, e lokelang ho tsoa oli.

Oilway:

Liphasejene tsa oli tse entsoeng hampe li tla lebisa ho khathala ho feteletseng le ho bokellana ha carbon. Haeba tselana ea oli e koaletsoe ke libubble tsa moea, esita le motheo oa atomizer o lebelo ka ho fetisisa o tla khabisoa.

Ho finyella tatso e feteletseng, mocheso o loketseng oa atomization oa oli ea mosi ke ntho e hlokahalang. Ho bapisa thepa ea thermodynamic le matla a li-cores tsa ceramic atomizer ke senotlolo.

Mofuta oa e-liquid:

Koae e lahliloeng, e-mokelikeli o mongobo le o monate o phahameng o hloka ho khetha coil ea ceramic ea moriri o otlolohileng, hobane tsela ea moea e khuts'oane.

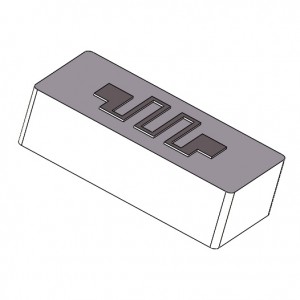

Bakeng sa phetoho ea likulo le ho lahloa ha e-mokelikeli o mocha, o hloka ho khetha coil e sephara ea ceramic.

Matla:

<7W khetha coil e teteaneng ea ceramic, eo ka ho phatloha ho matla, e hlokang feela matla a tlase ho fihlela mocheso o loketseng oa atomization;

> 7.5W khetha coil ea ceramic ea SMD, e hlokang matla a phahameng ho finyella mocheso o lakatsehang oa atomization.

Viscosity ea mokelikeli oa koae:

The viscosity ea e-mokelikeli ama ka ho toba mocheso atomization. Ka mor'a ho fumana viscosity ea e-liquid, coil ea ceramic ke khetho e ntle ka ho fetisisa. Lebelo la ho tsamaisa oli ke lebelo la ho tsamaisa oli le hlokahalang ho fihlela mocheso o nepahetseng oa atomo. Eseng kapele haholo, eseng butle haholo.